My country's static sealing materials and products have reached a very high level. Static sealing depends on closing the gap between the joint surfaces to achieve a sealing effect. According to different media, different working temperature and different sealing application environment to choose. In order to respond to the sealing requirements under high-speed, high-pressure and high-temperature conditions, my country's scientific research institutions have actively carried out research on materials and products. At present, a series of products have been formed to solve the urgent demand for sealing technology in the hydraulic and pneumatic industries, and the product level is continuously improved.

The high-speed rotating seal product is a hydrodynamic oil seal designed by the principle of fluid mechanics. This structure organically unifies the sealing and lubricating functions, reduces the working temperature, reduces the friction and wear of the lip, and doubles its service life compared with similar products.

It is reported that my country's self-developed high-performance sealing materials and products have been widely used in aerospace, aviation, weapons, ships, civil machinery and other fields. They are used for sealing, anti-wear sleeves, high pressure and high temperature gas sealing plugs, and reciprocating sealing and radiation-proof sealing materials are also promoted on special ships.

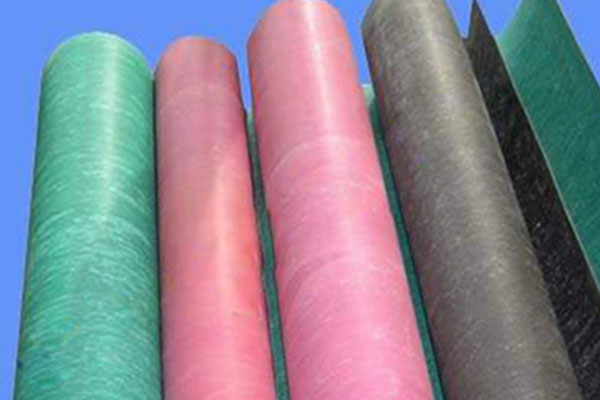

Static sealing products include seals of various sizes (O-rings, Y-rings, V-rings and various other non-standard gaskets, sealing rings, etc.), which are mainly used for various flat static seals and end guide grooves Seals, cylindrical static seals, dustproof seals, window frames, door seals, etc., have provided high-performance sealing products for various new special equipment, aerospace technology and civil vehicles.

The temperature adaptation range of rubber products is wide. Among them, special silicone rubber varieties with a wide temperature range include high temperature resistant, ablation resistant, high-strength, ultra-low temperature, etc., and have the ability to further research and develop, and can provide various O-shaped, special-shaped sealing rings, gaskets, etc. Sealing products; special nitrile rubber has excellent properties, such as oil resistance, high and low temperature resistance, high strength and high elasticity. The material technology is mature and the process is stable. It can withstand most hydraulic oil, mechanical oil and lubricating oil. Wide applicable temperature range, generally 50℃~130℃, can withstand high temperature of 150℃ in a short time, can be used to manufacture fixed or movable seals, valve parts and various gaskets, non-asbestos gaskets, sealing strips , Etc. to work in various oils.

High-speed rotating seal products are hydrodynamic oil seals designed using the principles of fluid mechanics. This structure organically unifies the sealing and lubrication functions, reduces the working temperature, and reduces the friction and wear of the lip. Compared with similar products, its service life is doubled.

The hydrodynamic oil seal made of low-friction fluorine rubber not only adapts to higher linear speed and harsh use conditions, but also reduces the processing requirements of the shaft, can adapt to eccentricity of 0.25mm or greater, and has a relatively long use The life of the oil seal is greatly extended, and it has passed the test of linear speed 20-25m/s, pressure 0.01-0.05MPa, working temperature -40-180℃ and 800h bench. It can provide a series of products in line with national standards and services such as performance evaluation and evaluation.

The above is all that the non-asbestos board manufacturers bring to you. Learn more about non-asbestos rubber sheets, non-asbestos fiber boards and other related knowledge, welcome to consult Xaar Sealing Technology, we will bring you more knowledge!