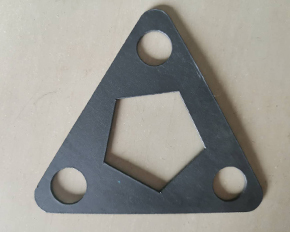

Product Name: 5350 Gasket

product description:

Non-asbestos gasket is a non-asbestos environmentally friendly sealing gasket material made of fiber rubber filler and processed by advanced calendering technology. Because of its excellent sealing and torque retention, outstanding oil resistance, chemical corrosion resistance, and refrigerant resistance, it can be widely used in various industries and has anti-flange bonding treatment on both sides.

Application medium: various gases, water, steam, chemical solvents and various oils, etc.

Industry equipment: Products are widely used in power generation, metallurgy, shipbuilding, petrochemical and other industrial applications such as water, gas, oil and other media sealed pipeline flanges, valves, heat exchangers, pressure vessels, mechanical equipment and engines, compressors, internal combustion engines , Machinery, instrumentation, heating and other industrial equipment.

The function of the gasket is to prevent the leakage of the sealing medium. The way of leakage can be divided into interface leakage and immersion leakage. The reason for the formation of interface leakage is usually due to the loosening of the pressure between the sealing surfaces, the aging, deformation, corrosion, wear or burning of the sealing surface, and the existence of mechanical vibration under working conditions. Immersion leakage is related to the type of gasket material, production method, nature of the sealing medium, working pressure, temperature and other factors.

The main features of non-asbestos gaskets:

1. 100% asbestos-free, new environmentally friendly sealing materials, can be exported to major developed countries such as Europe and the United States.

2. Good temperature resistance, pressure resistance and compression resilience

3. Wide applicability, oil resistance, medium resistance and air tightness.

4. High mechanical strength materials are easy to cut and shape.

Theoretically, it is impossible to completely contact the sealing surface even if the gasket is used, so there are no microscopic channels or gaps. Although these channels are very small, they are still relatively small compared to the molecular volume of the fluid medium. If it is large enough, it is impossible to completely block the fluid at the edge of the sealing surface. There will always be some fluid entering between the sealed touch surfaces, and chaotic fluid dynamics and thermodynamic processes will occur between them.

The main purpose of non-asbestos gaskets: static sealing of industrial pipeline flanges in ships, oil refining, chemical industries, etc.

Remarks: The product can be coated with graphite and anti-sticking agent according to customer requirements, and metal wires can be clamped with a thickness of 0.8mm or more; gasket materials with a thickness greater than 3.0mm are not subject to transverse tensile strength test; gasket materials reinforced by wire mesh are not Do transverse tensile strength and nitrogen leakage rate tests.

The main factors that affect the sealing are the following conditions: the appearance of the sealing surface; the contact width of the sealing surface; the nature of the fluid; the fluid temperature; the material of the gasket; the preload applied to the sealing surface; the influence of other external conditions (mainly the system Vibration, connector deformation, deviation of installation direction, etc.). If you want to make the seal reliable, you must carefully consider the above factors, and the quality and selection of the gasket is also very important.