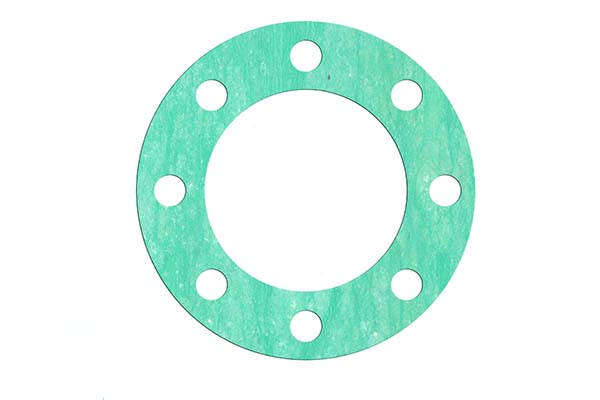

Traditional asbestos materials have been used in China for a long time. After China joined the WTO, various domestic industries are facing foreign challenges. The automobile industry is at the forefront of industrial reforms. Volkswagen and General Motors in the United States, as giants in the automotive industry, introduced the concept of asbestos-free gaskets to China. With the rapid development of the industry and more and more foreign auto companies investing and building factories in China, the non-asbestosization of auto parts has begun. In the petrochemical and shipbuilding industries, the chemical corrosion of asbestos to steel is usually a hidden danger for major accidents; in the refrigeration industry, especially air conditioners and refrigerators are closely related to people's lives. Asbestos can cause great harm to the human body and the environment. The following non-asbestos rubber sheet manufacturers will introduce to you the rebound rate and compression rate of gaskets.

The compression and resilience rate of DNV-28090-2.ASTM-F35-87 gasket is expressed as a percentage. The compression is to make the asbestos-free gasket fill the roughness and the orchid surface insufficient to achieve the sealing effect. Related to torque. The compressibility of the gasket is a range, not a set value. Unless the flange surface is uneven or has large defects, the compressibility value will not have much influence on the sealing of ordinary flanges. Larger amounts of compensation or non-metallic flange surfaces require gaskets with smaller torque and sufficient pressure to maintain compressibility. Therefore, resilience is a more important parameter: restoring force is the ability to maintain the bolt torque so that the flange surface will not loosen to maintain the seal. For sealing, rebound is more practical than compressibility.

1. Measurement method of resilience-Microscopic measurement and display method of rubber wool liquid covering film.

2. Rebound rate-the national standard requires a pass rate of more than 17%. When using gaskets, the greater the rebound rate, the better.

3. The compression rate is -18%-30% qualified. When using gaskets, the larger the compression rate, the better.

Huaian non-asbestos board

Compressibility and resilience calculation method

(hi-he)/hi *100% = shrinkage (%)

hd/(hi-he)*100%=Resilience (%)

hi = original enjoyment of gasket, he = thickness after compression, hd = thickness after compression and rebound

4. The experimental pressure at room temperature is usually 70 MPa, and different materials require different experimental pressures. According to the literature, the larger experimental pressure is 70 MPa.

5. The effect of temperature on the elasticity and compression rate of the gasket. As the temperature increases, the compression rate increases and the elasticity decreases.

6. Classification of spiral wound gasket: W, V spiral wound gasket. Because the V-shaped structure is relatively simple and the overall performance is better, it is currently widely used in large-diameter medium and low-pressure equipment and some high-pressure pipelines.

7. Factors affecting V-shaped gaskets: V-shaped metal wound gaskets are easy to fall off and crush due to poor deformability, but their compression resilience is better under low and medium pressure.

The above is all what Huaian non-asbestos board manufacturers have introduced for you. To learn more about sealing gaskets and non-asbestos rubber sheets, please come to consult!