Influence of asbestos-free gasket thickness:

Under the same compaction load and the same medium pressure, the leakage rate decreases as the thickness of the gasket increases. This is because under the same axial load, thick gaskets have greater compression rebound. When the initial sealing conditions are reached, thick gaskets with larger elastic reserves can compensate better than thin gaskets. The relative separation between the sealing surfaces caused by the pressure of the medium keeps a large residual compressive stress on the gasket surface, thereby reducing the leakage rate. But it cannot be said that the thicker the gasket thickness, the better the sealing performance. This is because the thickness of the gasket is different, and the conditions for establishing the initial seal are also different.

Due to the friction on the end surface, the surface of the gasket is in a state of three-dimensional compression stress, and the material's anti-deformation ability is relatively large. The influence of the end is small, and its resistance to deformation is also small. Under the same preload, the middle of the gasket is more likely to undergo plastic deformation than the surface of the gasket. At this time, it is more difficult to establish the initial seal. Therefore, when the thickness of the gasket reaches a certain value, the sealing performance will not change or even deteriorate. In addition, the thicker the gasket, the larger the cross-sectional area of penetration leakage and the greater the penetration leakage rate.

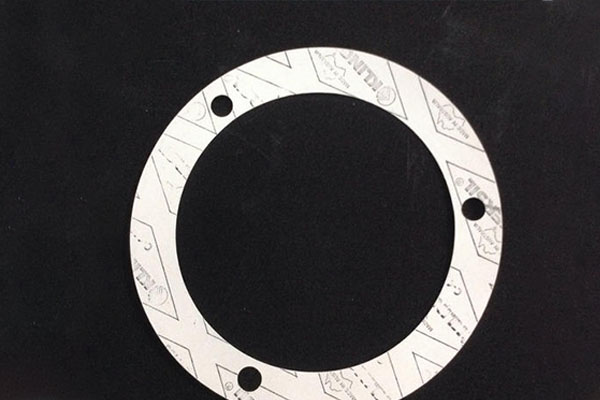

Influence of gasket width:

Within a certain range, as the width of the gasket increases, the leakage rate decreases linearly. This is because the medium leakage resistance within the effective width of the gasket is proportional to the length of the leakage channel (proportional to the width of the gasket). But it cannot be said that the wider the gasket, the better, because the wider the gasket, the greater the surface area of the gasket. This will produce the same compressive stress on the gasket, and the bolt force of a wide gasket is greater than that of a narrow gasket. a lot of.

The influence of the cross-sectional shape of metal ring washers (octagonal washers and oval washers):

The fit of the octagonal seal ring and the flange groove should be in surface contact. Compared with oval ring washers. Although it is not easy to make close contact with the flange groove, it can be used again, and because the section is straight, it is easy to process. The oval gasket is in contact with the flange groove line, and the sealing performance is good, but the processing accuracy is high, which increases the manufacturing cost, and the oval gasket cannot be reused.